Assurance Qualité pour nos douches

LG INDUSTRIES prend la qualité très au sérieux. Pour assurer que chaque douche répond à nos normes élevées, nous avons équipé nos laboratoires d’un banc de test dédié exclusivement à l’évaluation des douches. Cet équipement de pointe nous permet d’exécuter des tests rigoureux sur plusieurs aspects critiques de nos produits.

Nous vérifions méticuleusement l’étanchéité, garantissant que chaque douche est parfaitement imperméable et apte à offrir une expérience sans fuite. La résistance des matériaux est également testée, confirmant la durabilité et la robustesse de nos produits sous des conditions d’utilisation réelles. Enfin, le bon fonctionnement de tous les composants est contrôlé, afin de garantir que chaque douche fonctionne parfaitement avant sa mise sur le marché.

Grâce à ce processus de test exhaustif, nous pouvons promettre à nos clients des produits d’une qualité irréprochable, synonymes de fiabilité et de longévité. LG INDUSTRIES s’engage à n’offrir que le meilleur, en s’appuyant sur des technologies avancées et un engagement inébranlable envers l’excellence.

Excellence et Fiabilité de notre robinetterie

La qualité, la sécurité et la durabilité de nos mitigeurs sont nos priorités absolues. Pour garantir que chaque produit réponde à nos standards élevés, nos mitigeurs subissent des tests rigoureux sur des bancs de test spécialisés, situés dans nos installations à Phalempin.

Ces tests approfondis permettent d’évaluer la performance et la robustesse de nos mitigeurs dans des conditions simulant l’utilisation réelle. Chaque produit est vérifié pour sa capacité à résister aux pressions et variations de température, assurant ainsi une fonctionnalité optimale et une longue durée de vie.

En investissant dans ces technologies de pointe, LG INDUSTRIES s’engage à fournir des solutions de robinetterie synonymes de sécurité et fiabilité, renforçant ainsi la confiance de nos clients et établissant de nouvelles normes d’excellence dans le secteur.

Banc de test en eau : garantir la performance de nos mitigeurs

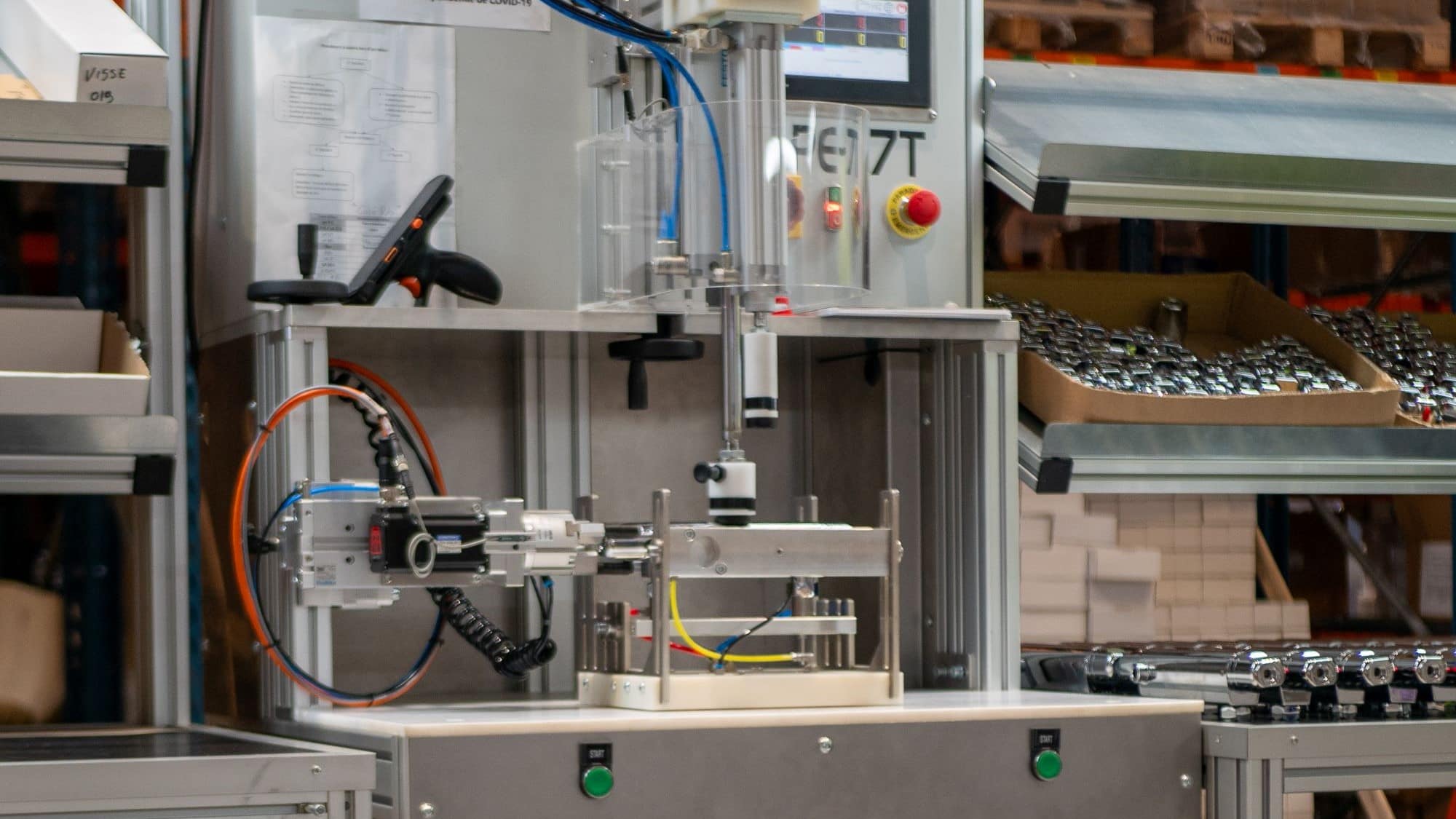

Nous utilisons un banc de test en eau de pointe pour garantir que nos mitigeurs répondent aux plus hauts standards de qualité et de performance. Ce dispositif est conçu pour simuler des conditions d’utilisation réelles, en soumettant nos produits à une série d’évaluations critiques.

Le banc de test en eau nous permet de vérifier plusieurs aspects essentiels de nos mitigeurs :

- Étanchéité : nous nous assurons que chaque mitigeur est parfaitement scellé pour éviter toute fuite, même sous des conditions d’utilisation prolongées.

- Débit et performance : en testant le débit d’eau, nous confirmons que nos mitigeurs fournissent un flux d’eau constant et efficace, répondant aux attentes de nos clients en matière de confort et d’efficacité.

- Contrôle de la température : chaque mitigeur est évalué pour s’assurer qu’il régule la température de l’eau de manière précise et stable.

- Résistance à la pression : nos produits sont soumis à des variations de pression pour garantir leur robustesse et durabilité, même dans des conditions de forte sollicitation.

Grâce à ces tests rigoureux, LG INDUSTRIES s’engage à offrir des solutions de robinetterie qui sont non seulement performantes mais aussi fiables, assurant satisfaction et tranquillité d’esprit à nos clients.

Banc de test en air : précision et fiabilité pour nos mitigeurs

L’innovation et la qualité passent aussi par l’utilisation de notre banc de test en air, une technologie avancée dédiée à l’évaluation des mitigeurs. Ce banc utilise de l’air comprimé pour tester l’étanchéité et la résistance de nos composants, offrant une méthode délicate mais efficace pour garantir l’excellence de nos produits.

- Détection de micro-fuites : l’utilisation de l’air comprimé permet de repérer des fuites potentielles de manière extrêmement précise, bien au-delà des capacités offertes par les tests à l’eau. Cela nous permet de détecter et de corriger les micro-fuites avant que nos produits n’atteignent le consommateur.

- Simulation sans eau : ce procédé de test est non seulement efficace, mais aussi respectueux de l’environnement, puisqu’il nous permet de réaliser des simulations de performance sans consommation d’eau.

Tous nos mitigeurs, testés à l’aide de ces bancs, sont conçus pour être robustes, performants et conformes aux exigences les plus strictes. En outre, chaque produit bénéficie de la norme NF, garantissant qu’il répond aux standards de qualité et de sécurité les plus élevés de l’industrie.

Grâce à ces bancs de tests de pointe, LG INDUSTRIES réaffirme son engagement à offrir des solutions de robinetterie inégalées, où précision et durabilité sont les maîtres mots.